Despite several global challenges, the construction industry is still experiencing robust growth. Effective architectural and MEP (mechanical, electrical and plumbing) design holds the key. Cost-effective and high quality architectural and MEP design services can have a noticeable effect on the construction industry’s progress. Interestingly, outsourcing production support for drafting, Revit modelling, Revit MEP and MEP coordination presents an expedient opportunity to save time and money.

Just what services can offshore design partners offer?

Although, offshore design support services abound, some of the most useful services that can be outsourced are MEP drafting, MEP modelling, MEP coordination, architectural drafting, architectural modelling and rendering. We look at what these services require and what they can deliver:

MEP Drafting:

Designs and marked images received as input are converted to MEP CAD drawings

MEP Modelling:

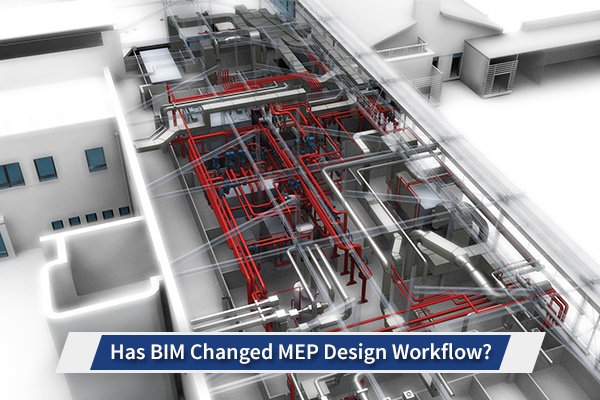

MEP CAD drawings used as input can generate MEP systems that define spaces and zones in mechanical, electrical, plumbing and fire models for all stages of the MEP design process, such as concept, tender, contract, coordination, approval, construction and as-fitted stages.

MEP Coordination:

MEP models can be spatially coordinated with building services (HVAC, pipework, public health and electrical systems) with other disciplines making up the building structure, architectural elements, fabric and external envelope (steel, concrete, false ceilings, etc.) to ensure there are no clashes (validated using clash detection software tools), represent mechanical components accurately, help create views, sections and detailed drawings easily and quickly, provide easy communication, as the 3D model can be viewed and walked through for demo, review, value engineering or QC purposes by building services trades.

Architectural Drafting:

Architectural CAD drafting services can be provided for all stages of a project, including tender, planning, construction and facility management for industrial, commercial, retail and residential projects. Design partners can deliver complete construction drawing sets (incorporating space planning, interior design and construction). Sheets (plans, elevations and sections) can be created.

Architectural Modelling:

Architectural 3D modelling services increasingly use Collaboration for Revit (C4R) and BIM 360 Team, a cloud-based tool on Revit, so that teams from different locations can work on the same model. Different kinds of models that can be provided are Revit BIM 3D models, which can incorporate changes to schedules, plans, elevations, sections or the 3D model itself, resulting in coordinated updates to all corresponding areas, point cloud 3D BIM models, that take 3D laser scan data in the form of ‘point cloud’ data and use it to create accurate Revit BIM models, 3D CAD building models, created using Autodesk Revit, ArchiCAD and AutoCAD Architecture by using 2D layout plans and elevations as a starting point, SketchUp models, which have the flexibility of being used in a number of other applications, including Revit, AutoCAD and virtual software applications, 4D CAD models, which are 3D models with the added element of time-based scheduling.

Architectural Rendering:

Architectural 3D rendering is an efficient communication tool for internal design approvals and reviews during the conceptualisation and design phases. It helps construction teams view proposed layouts and is also used for effective marketing and presentation. Renderings are created from detailed 3D models (which could be in Revit or AutoCAD) using plans/elevations. The 3D model is then exported to 3ds Max where textures, materials, reflection, depth, lighting and other features are added.

For many companies, these services can be expensive, time-consuming and require significant investment in software, hardware and training. Offshore design partners, especially in countries like India, offer these services at cost-effective rates, quicker turnaround times and of high quality. There are several reasons for this.

Benefits of Outsourcing Design Services

Architects and engineers offshore are well qualified and have the experience to provide high quality design services. Companies in this industry have been providing these services for decades and are fully cognisant of diverse global business requirements. Other reasons include:

- Lower Costs - Design services are provided at affordable rates, resulting in Western companies saving designing costs, without compromising quality.

- Infrastructure - Overseas design support teams have access to sound technical infrastructure, generally working on cloud-based storage and high-security data back-up solutions.

- Quality Control - The quality checking processes ensure that the design projects delivered are accurate and error-free.

- Latest Technology - Software, tools and technology used are the latest available, including AutoCAD, Revit, Inventor, SolidWorks, 3ds Max, etc.

- Security - Confidentiality agreements and strictly monitored data security ensure intellectual safety.

- Skilled Personnel - Architectural and engineering teams are put through many comprehensive sessions of hands-on work, making them well capable of dealing with even the most complex requirements.

- Fast Delivery - Multiple teams, dedicated teams and global delivery centres follow an efficient process to complete projects on schedule.

So, offshore drafting, 3D modelling, MEP coordination with Revit MEP support and Revit MEP resources and rendering services provided by reputable offshore design partners may lead to an efficient business process that works out to be economic, fast and reliable for the long term.