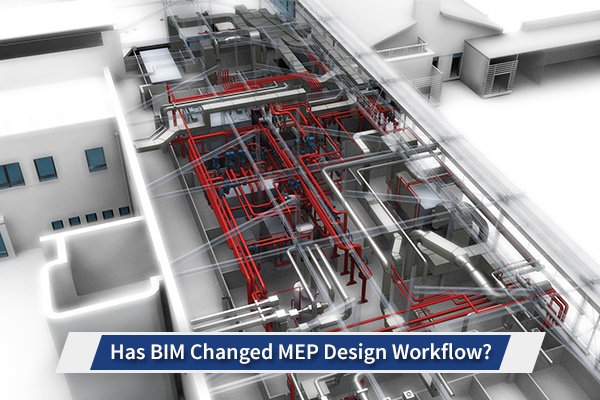

BIM Influence on MEP Design Workflow

Critical to effective construction, MEP (M&E or mechanical, electrical, plumbing) design is both one of the key features of a structure and also the one design feature that most people don’t want to deal with, unless something goes terribly wrong with any particular aspect of it. This makes it all the more important to make MEP design as precise as possible. Over time, MEP design has improved and evolved in many ways, but with the arrival of BIM (Building Information Modelling) technology, MEP design has seen modifications in its workflow as well. The workflow of MEP design has been significantly influenced by BIM technology, specifically the roles of the MEP designer and the MEP contractor.

Currently, there are five different MEP design workflow scenarios that exist. They are as follows:

- Traditional 2D design and 3D BIM coordination

- 3D MEP design and 3D BIM coordination

- Designers 3D BIM design and coordination

- Contractor 3D BIM design and coordination

- General contractor 3D model coordination

Designers 3D BIM MEP Design and Coordination

This MEP design workflow method is a direct consequence of BIM and promotes the benefit of BIM more significantly, as it gets closer to the ‘virtual design and construction’ aims of the industry. In this workflow, the approach of the design engineer is to create a BIM model that is spatially coordinated, using the actual specified components for the project. Typically, the consultant during this phase will have more time to create the model, allowing him to absorb the changes from structural and architectural disciplines as they progress through the detailing stages. Since the model is then coordinated with the structure and architecture as well as other MEP services, the consultant can create a model according to installation standards and which is more usable by an installer or fabricator.When the model in this workflow method is passed on to a contractor, the contractor may still wish to make final changes and adjustments in a round of value engineering. Typically, the contractor will use the same model in this workflow and make changes to the model provided by the MEP design consultant. Additionally, it is probable that the consultant engineer will not have provided invert (height) levels or dimensions from gridlines and walls for the MEP services on his drawings. In such cases the contractor will therefore have to create more detail in the drawings, but again, the contractor could use the consultant’s drawings and progress them in more detail for his/her use. This design workflow will require competent BIM coordination and MEP modelling teams and resources. XS CAD, with its large MEP coordination team and MEP engineering design team, which consists of mechanical and electrical engineering professionals, is well placed to deal with such projects for companies based in the USA, UK, Canada, Australia and New Zealand. As all are regions where BIM is now the preferred solution, XS CAD, with more than 16 years’ experience and a presence in each market is an ideal option for such companies.

No comments:

Post a Comment